Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

PRODUCTS

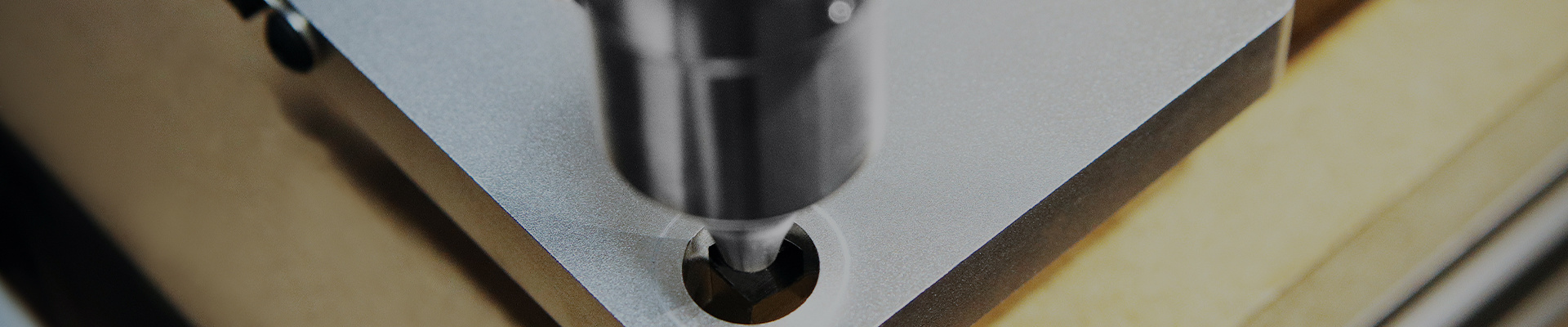

Quality Sheet Metal Fabrication

Sheet metal fabrication is the process of shaping and manipulating thin metal sheets to create various products and structures.

Category:

Sheet Metal Fabrication

Keyword:

Xiamen Biaoyuan Precision Hardware Industry Co.,Ltd

Product Details

|

Name |

Sheet metal fabrication |

|

Material |

Steel, Stainless Steel, Brass, Copper, Aluminum etc |

|

Processings |

Laser Cutting, CNC punching, Stamping, CNC Bending, CNC Milling, Threading, Riveting, Welding, PEM etc |

|

Surface Treatment |

Brushing, Polishing, Electrophoresis, Anodized, Powder Coating, Zinc Plating, Chrome Plating, Nickel Plating, Tin plating etc |

|

Logo |

Silkscreen printing, Laser engraving ect. |

|

Size |

According to customer’s drawing or sample |

Sheet Metal Fabrication is the process of shaping and manipulating sheet metal to create various components and structures. It involves a series of techniques such as cutting, bending, forming, and joining. Skilled craftsmen use advanced tools and machinery to transform flat sheets of metal into complex shapes with precision. This process is crucial in industries like aerospace, automotive, and construction. Sheet metal fabricated products offer strength, durability, and aesthetic appeal. From custom enclosures and ductwork to intricate metal parts, the possibilities are endless. The fabrication process ensures that the final products meet exact specifications and quality standards. It requires expertise in material selection, design, and manufacturing techniques. With the advancements in technology, sheet metal fabrication is becoming more efficient and innovative, enabling the creation of high-quality and unique metal products for diverse applications.

Sheet metal fabrication is the process of manufacturing custom metal parts and components through a series of steps that include cutting, bending, and assembling. This versatile process allows for the creation of a wide range of products, from simple brackets and enclosures to complex machinery and architectural features.

The first step in sheet metal fabrication is cutting, which involves using tools like shears, lasers, or waterjets to cut the metal into the desired shape and size. The type of cutting tool used will depend on the thickness and type of metal being worked with, as well as the complexity of the design.

Next, the cut pieces are bent and formed into their final shapes using a variety of tools and techniques. This can include press brakes, roll formers, and CNC folding machines. The precision and accuracy of these processes are critical to ensuring that the finished product meets the required specifications.

Previous

Next

Previous

Next

Leave us a message

RELATED PRODUCTS

Let’s Talk

We can help you figure out your needs.